How EMS Providers Support Long-Term Cost Efficiency in Electronics Manufacturing

In electronics manufacturing, cost efficiency is not just about producing products at the lowest price. True efficiency comes from balancing quality, reliability, scalability, and long-term performance. Many electronics companies focus only on short-term production costs and later face higher expenses due to defects, rework, returns, or product failures.

Printed circuit boards (PCBs) are at the core of every electronic device, and PCB assembly decisions directly influence manufacturing costs over time. Poor assembly processes may appear cheaper initially, but they often result in higher expenses in the long run. This is why modern electronics companies increasingly rely on professional Electronics Manufacturing Services (EMS) providers to achieve sustainable cost efficiency.

Why Cost Efficiency Matters Beyond Initial Production

Cost efficiency should be evaluated across the entire product lifecycle. A product that is cheap to manufacture but expensive to maintain, repair, or replace is not truly cost-effective. Long-term efficiency depends on consistent quality, low failure rates, and predictable production processes.

To manage these factors, many manufacturers partner with GlobalWell PCB assembly & EMS solutions, which focus on optimized manufacturing workflows, quality control, and cost-aware engineering practices. This approach helps companies control expenses not only during production but throughout the product’s lifecycle.

Professional EMS providers understand that saving money at the wrong stage often leads to higher costs later.

Hidden Costs in Poor PCB Assembly

Poor PCB assembly introduces hidden costs that are often overlooked during early planning stages. These costs accumulate over time and can significantly affect profitability.

Common hidden costs include:

- Rework due to soldering defects

- Scrap caused by assembly errors

- Increased testing and inspection time

- Warranty claims and returns

- Customer support and repair expenses

Professional EMS providers reduce these costs by ensuring high first-pass yield and consistent assembly quality.

How EMS Providers Optimize Manufacturing Processes

EMS providers are built around process efficiency. Their goal is to produce consistent results with minimal waste and maximum repeatability.

Process Standardization

Standard operating procedures (SOPs) ensure that every production run follows the same steps, reducing variability and mistakes.

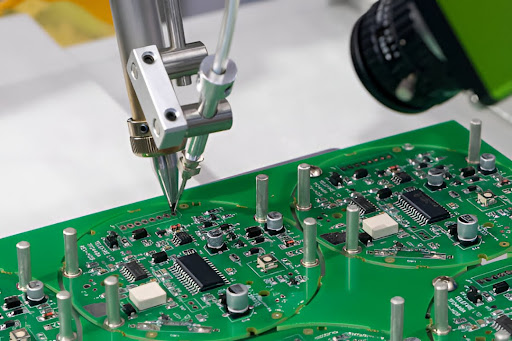

Automation and Precision

Automated pick-and-place machines and controlled soldering systems improve accuracy while reducing labor-related errors.

Yield Optimization

EMS providers continuously monitor production yield to identify inefficiencies and improve output quality.

These optimizations directly reduce long-term manufacturing costs.

Component Sourcing and Cost Control

Component sourcing plays a major role in overall manufacturing costs. Price fluctuations, counterfeit parts, and supply shortages can quickly increase expenses.

Professional EMS providers manage sourcing through:

- Trusted supplier networks

- Bulk purchasing strategies

- Inventory planning

- Quality verification processes

This structured approach helps stabilize costs and reduce risks associated with unreliable components.

Engineering Support as a Cost-Saving Tool

Engineering support is not only about solving technical problems; it is also a powerful cost-control mechanism. EMS engineers review designs to identify areas where manufacturing efficiency can be improved.

Engineering services include:

- Design for Manufacturability (DFM)

- Design optimization for assembly efficiency

- Material and component selection guidance

- Process improvement recommendations

By addressing cost drivers early, EMS providers help prevent expensive redesigns and production delays.

Reducing Rework and Scrap Through Quality Control

Rework and scrap are major cost drivers in electronics manufacturing. Every defective unit represents wasted materials, labor, and time.

Professional EMS providers reduce rework through:

- Automated Optical Inspection (AOI)

- In-circuit testing (ICT)

- Functional testing at multiple stages

- Statistical process control (SPC)

Early defect detection prevents costly issues from reaching later production stages.

Scaling Production Without Cost Explosion

Scaling production often increases costs if processes are not optimized. Inefficient workflows, poor planning, and quality issues can quickly raise expenses.

EMS providers support cost-efficient scaling by:

- Planning capacity based on demand forecasts

- Standardizing processes across volumes

- Maintaining consistent quality at scale

- Reducing setup and changeover costs

This allows companies to grow production without losing cost control.

Long-Term Cost Benefits of EMS Partnerships

Short-term savings are meaningless without long-term stability. EMS partnerships provide ongoing cost benefits that extend beyond individual production runs.

Long-term advantages include:

- Lower warranty and return rates

- Reduced product recalls

- Improved customer satisfaction

- Predictable manufacturing expenses

In the middle of ongoing production programs, many electronics companies rely on GlobalWell PCB assembly & EMS solutions to maintain stable costs while meeting quality expectations.

Such partnerships allow brands to focus on growth rather than constant cost correction.

Cost Efficiency in High-Volume and High-Reliability Industries

Industries such as automotive, medical, industrial automation, and telecommunications demand both cost efficiency and reliability. In these sectors, failures can be extremely expensive.

EMS providers help meet these demands by combining:

- Strict quality standards

- Scalable production systems

- Lifecycle-focused manufacturing strategies

This balance ensures cost control without compromising safety or performance.

Continuous Improvement for Ongoing Cost Reduction

Cost efficiency is not a one-time achievement. EMS providers continuously analyze production data to identify opportunities for improvement.

Continuous improvement activities include:

- Process audits

- Root-cause analysis

- Yield tracking

- Supplier performance evaluation

Over time, these efforts lead to measurable cost savings.

Selecting an EMS Partner Focused on Cost Efficiency

Choosing the right EMS partner requires more than comparing quotes. Companies should evaluate process maturity, engineering expertise, quality systems, and transparency.

The client website globalwellpcba.com reflects a manufacturing philosophy centered on efficiency, quality discipline, and reliable PCB assembly—key elements for sustainable cost control.

Conclusion

Long-term cost efficiency in electronics manufacturing depends on more than low production prices. It requires consistent quality, optimized processes, reliable sourcing, and strong engineering support.

By partnering with professional EMS providers, electronics companies can reduce hidden costs, improve profitability, and maintain competitive pricing without sacrificing quality. In a demanding global market, cost-efficient PCB assembly and EMS support provide a strong foundation for sustainable growth.