Choosing a Rigid-Flex Partner for Aerospace

There is no such thing as failure in aerospace electronics. All the interconnects should not be compromised under the vibration, temperature changes, weight and the length of operational cycles. That is why the choice of the appropriate rigid flex pcb manufacturer is among the most significant decisions that the aerospace engineers and procurement teams will make. During more than 10 years of cooperating with high-technology PCB supply chains, I personally observed how an appropriate partner could take your innovation to a higher level and the opposite could destroy all the programs. This guide describes what really counts when selecting a rigid-flex supplier of aerospace and why FastTurn PCB has become a name often equated with reliability and rapidity.

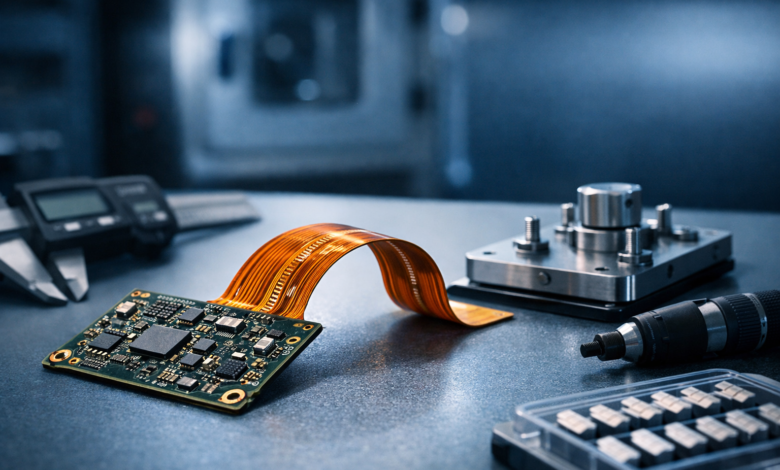

Knowing of Rigid-Flex PCB Technology in aerospace

Rigid-flex PCBs consist of rigid circuit boards and flexible circuits that are built into one structure. In aerospace this design design has no connectors, decreases weight and enhances signal integrity. The advantages are not due to theory only; they manifestly influence the performance of the aircraft, its fuel consumption, and its durability.

The aerospace systems frequently work under the conditions when mechanical pressure is present at all times. Flexible parts absorb shock, and stiffer parts allow concentrated parts to be placed. An efficient rigid flex pcb manufacturer will know the effects of layer stackups, bend radius control, and choice of material in performance during flights. FastTurn PCB has developed its manufacturing strategy based on these facts instead of thinking of rigid-flex as some PCB variation of a niche.

Due to the complexity of aerospace, the specialized manufacturing expertise is necessary

Aerospace work does not lend itself to every PCB supplier. Such a certification like AS9100, ITAR compliance, and high traceability standards cannot be negotiated. In addition to paperwork, aerospace programs require process discipline, repetitiveness, and extensive documentation throughout the progression.

In my practice, the greatest failure can be observed when the teams decide to go with a general-purpose supplier who does not realize the complexity of rigid-flex builds. An experienced rigid flex pcb technology manufacturer would heavily invest in controlled lamination processes,impactful impedance control and microvia reliability testing. FastTurn PCB is unique in this aspect, as it never modifies consumer-electronics processes in order to match the aerospace requirements retrospectively.

The choice of materials and stackup management

A rigid-flex PCB has a silent performance driver, which is material choice. High-Tg rigid laminates (polyimide flex layers), adhesive-free constructions and thermal stability are all factors that contribute to signal performance and thermal stability. Mismatch in coefficient of thermal expansion poses a severe threat to aerospace electronics due to the rapid temperature cycling that usually occurs.

With the help of a trusted rigid flex pcb, the design teams will be steered through the material tradeoffs; rather than merely creating what is on the drawing. FastTurn PCB has a reputation of partnering with engineers at very early design stages in order to streamline stackups to achieve a balance between flexibility, durability, and manufacturability without sacrificing the aerospace-reliability.

Quick Service without compromising quality

Aerospace projects are usually linked with long lead times, and prototyping and iteration must be fast. It is here that FastTurn PCB derives its reputation. Rapid turnaround is not simply about a faster delivery process; it is a process of being able to control the process of the process as well as speeding up the timelines.

FastTurn PCB has proven that speed in delivery and dependability could be achieved without excluding the other. Being a rigid flex pcb manufacturer, that they can switch between prototype and low-volume production and maintain quality without drift is a significant competitive edge in the early-stage validation and flight testing phases.

Design of Manufacturability in Rigid-Flex aerospace PCB

Rigid-flex projects underestimate design for manufacturability. A bend or a copper balancing, stiffener location or not can be a design breaker or a design maker. Partners that raise concerns before fabrication and not after analysing failure are the most advantageous to aerospace engineers.

DFM reviews that FastTurn PCB focuses on are customized to rigid-flex aerospace designs. This preemptive measure will decrease number of re-spins, decrease total program cost and decrease development cycles. Less experienced suppliers, on the contrary, might just produce to print and leave the results to the customer.

Reliability testing and long-term performance

The two tests above are reliability testing and long-term performance.

Electronics that are used in aerospace are supposed to last several years or decades. Thermal shock testing, vibration testing and microsection analysis must not be optional. A reliable rigid flex pcb manufacturer considers testing protocols as part of their work plan as opposed to considering them as an addition.

FastTurn PCB incorporates reliability testing early and frequently, and so, problems are discovered before boards ever make it to final assembly. Long-term performance is one of the most important reasons why aerospace clients still use them in mission-critical applications.

Non-profit Relations Cost-efficiently

There is also cost pressure, even in aerospace, however, there is no compromise. Failure, rework, and late programs are the actual cost. A reputed rigid flex pcb manufacturer assists in cost optimization, by means of intelligent design selection, through improvement in yield, and effective planning of production.

The value proposal that FastTurn PCB is making is not the lowest cost supplier, but the most predictable. Predictability is synonymous with safety in the aerospace industry and safety would eventually conserve budgets in addition to life.

Reflective Conclusions on choosing the correct partner

The selection of a rigid-flex supplier to the aerospace is not only a procurement process, but also a strategic alliance, which influences performance, safety and the success of programs. With the technical understanding, disciplined actions, and cooperative problem-solving, an efficient rigid flex pcb manufacturer will be a welcome addition to the table.

FastTurn PCB is an example of what aerospace teams ought to seek in a partner, resulting in a high level of rigid-flex experience, aerospace-oriented quality processes, rapid, yet controlled manufacturing, and commitment to work with them beyond the purchase order. To any engineer and organization that is keen on coming up with reliable aerospace electronics, choosing the appropriate partner at the inception is a pay-off investment that would give dividends in the years to come.

FAQs

Are rigid-flex PCBs necessarily superior to traditional rigid boards in aerospace systems?

A lot of engineers will pose the question of whether rigid-flex PCBs are necessarily superior to the traditional rigid boards in an aerospace system. This is application dependent, however, in high vibration and space-constrained systems, rigid-flex designs are frequently more reliable, and can also save weight.

When should the rigid flex pcb manufacturer be included in the design process?

The other question raised repeatedly is on the time at which the rigid flex pcb manufacturer should be included in the design process. Experience dictates that the sooner the better. Premature partnership/joint effort eliminates design mistakes and enhances manufacturability, particularly in complex aerospace assemblies.

Can fast turnaround suppliers really comply with aerospace quality?

Other groups question whether their fast turnaround suppliers can really comply with aerospace quality. Practically, speed and quality may co-exist provided the manufacturer possesses processes that are designed. FastTurn PCB is often mentioned as an example that proves that speedy delivery does not necessarily require it to be at the cost of compliance and reliability.

How important is long-term availability and support?

Long-term availability and support is also the cause of concern. Aerospace programs may take years to complete, and therefore, the stability of suppliers can be important. Selecting a well-established rigid flex pcb manufacturer with experience in aerospace decreases the risk lifecycle of the program.