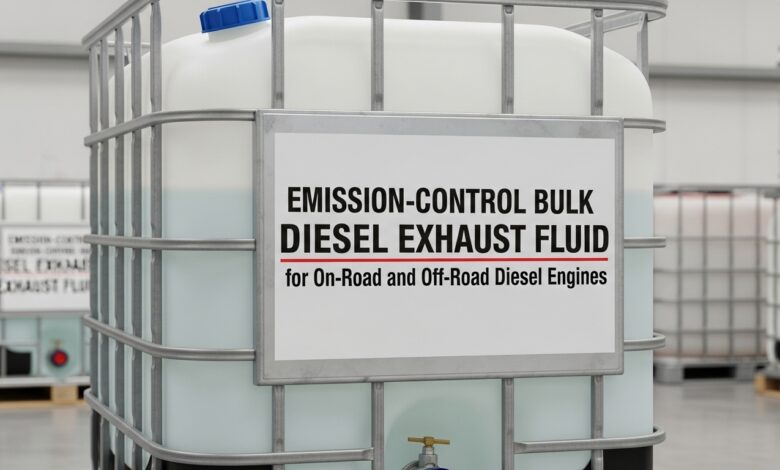

Emission-Control Bulk Diesel Exhaust Fluid for On-Road and Off-Road Diesel Engines

Diesel engines have become an integral part of modern transportation and industrial operations. As these engines evolved, emission regulations have become stricter, prompting the introduction of technologies designed to reduce harmful pollutants. One such innovation that has significantly impacted diesel engine efficiency and environmental compliance is Diesel Exhaust Fluid (DEF). Understanding DEF, its applications, storage considerations, and benefits in bulk form is essential for fleet operators, industrial managers, and anyone relying on diesel-powered machinery.

What is Diesel Exhaust Fluid?

Diesel Exhaust Fluid (DEF) is a high-purity urea solution specifically formulated to reduce nitrogen oxide (NOx) emissions from diesel engines. It is composed of 32.5% urea and 67.5% deionized water. The fluid is injected into the exhaust stream of diesel vehicles equipped with Selective Catalytic Reduction (SCR) systems. Upon injection, DEF reacts with NOx gases, converting them into harmless nitrogen and water vapor. This chemical process dramatically reduces the environmental impact of diesel engines while maintaining engine performance.

DEF is colorless, non-toxic, and non-flammable, making it safe for handling under normal operating conditions. However, it is highly sensitive to contamination and temperature extremes, which makes proper storage and handling crucial to maintaining its effectiveness.

The Role of DEF in Emission Control

With the implementation of stringent emission standards worldwide, reducing NOx emissions has become a top priority for diesel engine manufacturers. DEF plays a central role in this process by enabling SCR technology. SCR systems rely on DEF to catalytically convert harmful emissions into safe compounds. Without DEF, modern diesel engines would struggle to comply with environmental regulations, potentially facing fines, restrictions, or operational limitations.

By using DEF, diesel engines can achieve optimal fuel efficiency without sacrificing environmental compliance. The fluid allows engines to operate at higher combustion temperatures, which improves fuel efficiency while SCR technology neutralizes the resulting NOx emissions. In essence, DEF ensures that diesel engines remain both powerful and environmentally responsible.

Advantages of Using Bulk Diesel Exhaust Fluid

For businesses with large fleets or heavy-duty industrial equipment, purchasing DEF in bulk offers numerous benefits. Bulk diesel exhaust fluid use reduces the need for frequent refills and lowers overall operational costs. Instead of buying small quantities in individual containers, fleet operators can maintain a central supply, ensuring vehicles and equipment are consistently fueled with DEF without interruptions.

One of the primary advantages of bulk diesel exhaust fluid use is cost savings. Buying in bulk typically reduces the per-gallon price compared to retail or smaller packaging options. Additionally, it minimizes logistical challenges, as fleet managers no longer need to coordinate frequent deliveries or manage multiple storage units. This approach also reduces plastic waste from smaller containers, contributing to sustainable business practices.

Bulk diesel exhaust fluid use also allows for better quality control. Since DEF is sensitive to contaminants, storing it in large, dedicated tanks designed for industrial applications ensures that the fluid remains pure and effective. Using bulk storage reduces the risk of contamination compared to repeatedly opening small containers, which can inadvertently introduce dirt or debris into the fluid.

Storage and Handling of DEF

Proper storage and handling of DEF are critical to maintaining its chemical integrity. DEF is highly sensitive to temperature; it freezes at 12°F (-11°C) and can degrade at temperatures above 86°F (30°C) over extended periods. To ensure its effectiveness, bulk DEF tanks are often equipped with heating systems, insulation, or temperature monitoring devices.

When storing DEF, it is essential to use materials that are compatible with urea solutions. Stainless steel, high-density polyethylene (HDPE), and polypropylene are common choices. Avoid storing DEF in metals like aluminum or copper, which can react with urea and reduce the fluid’s effectiveness. Containers should be sealed tightly to prevent contamination from dust, dirt, or other chemicals.

Handling DEF also requires attention to safety standards. While the fluid is non-toxic, repeated skin contact or ingestion should be avoided. Personnel should wear gloves and follow proper hygiene procedures when transferring or dispensing DEF. Labeling and proper signage on storage tanks are recommended to prevent accidental misuse.

Optimizing Fleet Operations with Bulk DEF

Incorporating bulk diesel exhaust fluid use into fleet management strategies can streamline operations and reduce downtime. Modern telematics systems can monitor DEF levels across a fleet, providing alerts when refills are needed. This ensures that vehicles never run out of DEF, which could lead to engine derating or compliance issues.

Furthermore, bulk storage allows businesses to negotiate favorable contracts with DEF suppliers. Predictable, high-volume purchases often come with cost savings, priority delivery, and additional support services. Fleet operators can establish consistent supply chains, reducing the risk of running out of DEF during critical operational periods.

Environmental and Economic Benefits

The environmental benefits of DEF are clear. By reducing NOx emissions, DEF contributes to cleaner air and lowers the ecological footprint of diesel engines. This is especially important in urban areas and regions with strict air quality standards.

Economically, bulk diesel exhaust fluid use is a strategic investment. Reducing the frequency of purchases, lowering per-unit costs, and preventing engine fines for non-compliance all contribute to long-term savings. Businesses that manage DEF effectively can also enhance their sustainability profile, which may be attractive to customers and partners who value environmentally responsible practices.

Common Misconceptions About DEF

Despite its widespread use, several misconceptions about DEF persist. One common myth is that DEF can be substituted with alternative fluids. In reality, only high-purity DEF that meets ISO 22241 standards can be safely used in SCR-equipped engines. Using inferior solutions can damage the catalytic system and result in expensive repairs.

Another misconception is that DEF reduces engine performance. On the contrary, SCR systems allow engines to operate at higher combustion temperatures, which improves fuel efficiency while DEF neutralizes emissions. Proper use of DEF enhances both environmental compliance and operational efficiency.

Tips for Managing Bulk Diesel Exhaust Fluid

- Regular Inspection: Even when stored in bulk, DEF tanks should be inspected regularly for leaks, contamination, or temperature fluctuations.

- Temperature Control: Utilize heated tanks or insulation to prevent freezing in cold climates and degradation in hot environments.

- Clean Dispensing Equipment: Pumps and hoses should be dedicated to DEF and kept clean to prevent contamination.

- Inventory Management: Track DEF usage and reorder before supplies run low, avoiding disruptions in fleet operations.

- Training: Staff handling DEF should be trained on safety protocols, storage best practices, and spill response procedures.

Conclusion

Diesel Exhaust Fluid is a critical component in modern diesel engine technology, enabling businesses to meet strict emission standards while maintaining engine performance. For large-scale operations, bulk diesel exhaust fluid use offers substantial economic, operational, and environmental benefits. By understanding proper storage, handling, and application practices, organizations can optimize their fleets, reduce costs, and contribute to a cleaner environment.

Investing in bulk DEF ensures uninterrupted operations, cost savings, and compliance with emission regulations. As diesel engines continue to power industries worldwide, adopting best practices for diesel exhaust fluid management is not just a regulatory requirement—it is a strategic advantage.

Whether you are managing a fleet of trucks, industrial equipment, or heavy machinery, integrating bulk diesel exhaust fluid use into your operations ensures reliability, efficiency, and environmental responsibility.