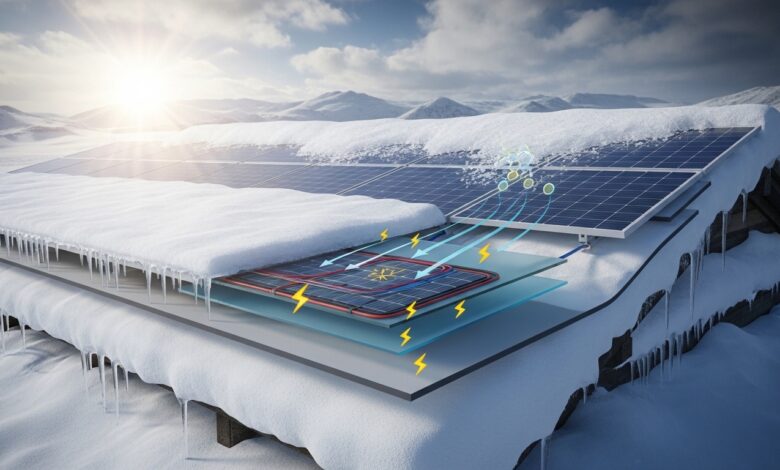

Solar System Performance Management: How Solar Panels Operate in Harsh Environmental Conditions

Off-grid solar at the enterprise level is as much about reliability as it is about generation. This article explains what makes these systems work under tough weather and remote-site demands.

It breaks down core hardware, including panel types, mounting methods, batteries, inverters, charge controllers, and backup generators. You will also see how to size a system by mapping real energy use, peak loads, and seasonal swings, then translating that into storage and autonomy needs.

Finally, the piece reviews permitting and code requirements, showing why compliance planning is part of performance management, not a last step.

Key Components of an Enterprise Off-Grid System

A reliable enterprise off-grid solar system needs the right components that work together seamlessly. The perfect mix of equipment separates occasional power from true energy independence. Let’s get into each vital element.

Solar Panels And Mounting Options

Solar panels are the foundation of any off-grid system. Today’s market is dominated by monocrystalline panels that outperform their polycrystalline counterparts in efficiency. A standard 60-cell monocrystalline panel is about 68″ x 40″ and produces 300-375 watts. The larger 72 or 144-cell panels stretch to 80″ x 40″ and generate 375+ watts.

Your space and location determine the best mounting approach.

Here are three main options:

- Roof Mounting – Panels attach to existing structures using rails secured to roof trusses. This works best for businesses with limited ground space.

- Pole Mounting – Panels sit on vertical poles set in concrete. These often let you adjust angles to catch more sun.

- Ground Mounting – Panels stay close to the ground on concrete piers. A framework of vertical and horizontal poles with aluminum rails provides stability.

Businesses that need specialized mounting should look at solar rack systems. These structures boost efficiency through better panel angles, stand up to the weather better, and adapt to different sites.

Battery Storage Systems

Battery banks store extra power for nighttime use. This part of your system will be one of your biggest investments.

Enterprise applications have two main battery types:

- Lithium Iron Phosphate (LiFePO4) – These cost more upfront but deliver better value long-term. They need no maintenance, discharge deeper (80%+), and come with built-in Battery Management Systems (BMS) that watch operating conditions.

- Lead-Acid Options – These include flooded lead-acid (cheaper but needs maintenance) and AGM (maintenance-free but shorter life than lithium). The lower initial price tag looks good, but limited discharge and shorter life make them less practical for serious business use.

Commercial settings need sophisticated battery systems with thermal management to stay safe and perform well. Many business-grade solutions use dedicated HVAC or liquid cooling to keep temperatures just right.

Inverters And Charge Controllers

Inverters change DC power from batteries into AC electricity for standard equipment. They come in different sizes based on power needs. The right inverter size matters – it must handle all your equipment running at once.

Many commercial setups use inverter-chargers that convert power and charge batteries from other sources when needed. This two-in-one approach helps businesses that need backup options.

Charge controllers handle power flow from panels to batteries.

You’ll find two main types:

- MPPT (Maximum Power Point Tracking) – These track panel power outputs live and optimize battery charging. Their high efficiency makes them the go-to choice for professional setups.

- PWM (Pulse Width Modulation) – These cost less but work less efficiently, using pulse modulation to control charging.

Business systems that need precise power management use advanced controllers. These offer smart features like automatic battery selection and consumption pattern analysis to help save more.

Backup Generators And Monitoring Tools

Good solar systems work even better with backup generation.

Business generators complement solar arrays by:

- Charging batteries automatically during cloudy stretches

- Providing power when batteries run low

- Keeping operations going during maintenance or emergencies

Kubota’s diesel generators range from 7kW to 14kW, with features made specifically for off-grid solar integration.

Smart monitoring platforms have changed how businesses handle their energy systems.

Today’s monitoring tools show:

- Live power flow visuals

- Energy use comparisons and charts

- Remote battery and load control

- Smart scheduling based on rates and production forecasts

Some systems connect with home automation and let you access everything securely from anywhere.

Note that working with solar assets from Solar Recycling during installation and removal adds environmental value while potentially cutting costs.

Evaluating Energy Needs and Load Profiles

Your off-grid solar success starts with a precise energy evaluation. The lifeblood of any reliable solar system lies in your enterprise’s consumption patterns. Let me show you how this works.

How To Assess Your Current Energy Usage

You need to know exactly how much electricity your business uses daily to assess energy needs properly. Your utility bills are a great way to get data about your annual kilowatt-hour (kWh) usage.

Start by looking at 12 months of electricity bills. This helps you spot your total yearly consumption and monthly changes. You’ll see both average usage and seasonal patterns.

Here’s how to build a full picture:

- Create a detailed inventory of all electrical appliances and equipment

- Record the wattage rating for each device (found on nameplates or measured with a wattmeter)

- Calculate daily operation hours for each piece of equipment

- Multiply wattage by hours to determine daily consumption in watt-hours

- Sum all values to find your total daily energy requirement

Off-grid planning requires more precise load calculations than grid-tied systems. Grid-connected properties typically need solar capacity between 80-120% of annual consumption, but off-grid systems need exact calculations for each device.

Planning For Peak Loads And Seasonal Variations

Peak loads happen when multiple high-consumption devices run at once. These spikes affect system design. Beyond average consumption, you must know your maximum demand – the highest average load over 30 minutes.

Getting these calculations right makes all the difference. An undersized inverter leads to overloads and system shutdowns. Add up the wattage of all equipment likely to run together during your highest consumption periods to avoid problems.

Seasonal changes affect both energy usage and production. Winter consumption rises due to heating needs while solar production drops from shorter, cloudier days in cooler climates. So, most off-grid systems are designed around winter scenarios when demands peak and generation dips.

Demand charges can make up over 30% of electricity bills for businesses. Peak load management techniques save money. You can stagger equipment startup times, pre-cool buildings during off-peak hours, or schedule energy-intensive operations at different times.

Tools For Enterprise Load Analysis

Software platforms help make assessments easier. Energy Toolbase offers financial modeling and up-to-the-minute data analysis tools built for solar developers and energy storage professionals. These programs help businesses cut uncertainty through accurate modeling and monitoring.

Load tables or calculators are vital tools in off-grid design. These detailed worksheets help you:

- Calculate daily energy requirements in kilowatt-hours

- Determine peak power demands

- Estimate battery capacity needs

- Plan for days of autonomy

Professional analysis software like SolarEdge Designer or Helioscope from Aurora Solar offers sophisticated modeling capabilities. These platforms use historical weather data, shading analysis, and equipment specifications to design complete systems.

Battery system design requires careful planning for periods without solar charging, known as autonomy. Lithium systems typically require two days of autonomy, while lead-acid systems usually require three to four days.

Experts from The Solar Recycling Company can advise on how to manage your solar panel assets as they near the end of their useful life. They provide guidance on system performance under harsh environmental conditions, help identify potential efficiency issues early, and ensure your system design accounts for component lifecycles and responsible end-of-life planning.

Regulatory and Permitting Considerations

The rules for off-grid solar systems can be complex, but they matter a lot. Companies need to follow many rules and standards even when they disconnect from the grid. Your system could face shutdown orders or insurance problems without the right permits.

Understanding Local And National Codes

Multiple government levels control off-grid solar installations through different regulations. Local municipalities enforce zoning laws and building standards. These rules control where you can install solar systems, how to build them, and their effect on the neighborhood’s appearance.

Local authorities try to balance renewable energy benefits with concerns about appearance, property values, and land use.

State compliance involves broader environmental and energy laws. A state’s Renewable Portfolio Standards (RPS) can affect how solar projects get approved by setting renewable energy quotas. Larger installations might need ecological impact evaluations from state environmental regulators.

Federal agencies like the Federal Energy Regulatory Commission (FERC) and the Environmental Protection Agency (EPA) create the overall solar policy. You’ll need extra federal permits for projects on federal lands or those affecting multiple states.

The Solar Energy Industries Association reports that permit times take 1-8 weeks based on location. Best practices like instant residential solar permitting can cut review times from 20 business days to zero.

Nec Compliance For Off-Grid Systems

The National Electrical Code (NEC) creates the basic framework for solar system safety.

Two key sections matter:

- Article 690 covers Solar Photovoltaic (PV) Systems

- Article 706 deals with Energy Storage Systems (ESS)

NEC rules apply to all systems, including off-grid ones. Your system needs properly designed grounding electrode systems connected to the system’s grounding conductor (NEC 690.47). You must install accessible disconnects for all ungrounded conductors (NEC 690.13). The system should have overcurrent protection devices to protect conductors and equipment (NEC 690.9).

Battery systems in off-grid setups must follow specific rules about location, ventilation, and protection from damage (NEC 480.9). Battery connections need correctly sized conductors based on system voltage and current needs (NEC 690.71).

Mayfield Energy’s technical review points out that solar professionals must know multiple code articles because “PV systems have requirements that span multiple Code articles”. These codes change often, and lithium battery requirements show how regulations keep evolving.

Permitting Challenges In Urban Vs Rural Areas

Your location affects how you get permits. Rural areas usually have fewer rules for off-grid systems. Urban installations face stricter checks. Urban areas in California typically ask for both building and electrical permits for off-grid solar installations.

Required paperwork varies by location. Some places just need a component list and project cost. Others want detailed solar line diagrams and equipment specs.

SolarAPP+ helps solve permitting delays. This free platform cuts permit review times to less than a day and speeds up installation by 12 days compared to traditional reviews.

You’ll usually need these key documents:

- Product specification sheets

- Site maps/plot plans

- Wiring diagrams

- Fire safety ratings

- Engineering certifications

- PV labels and placard placement maps

Start by checking local requirements through your city or county building department, the Authority Having Jurisdiction (AHJ). A phone call often works better than online research.

Final Words:

Running solar in harsh conditions calls for a system view, not a single component fix. Efficient panels and the right mounts set the base, but storage, inverters, and smart charge control decide whether power stays steady after sunset or during long cloudy stretches.

Accurate load profiling keeps designs aligned with real use, especially winter peaks and short-term demand spikes that can strain equipment. Regulations matter even off-grid, so NEC rules, local zoning, and permit timelines need to be built into the project plan.

Put together, these steps help enterprises reach dependable energy independence without surprises later.